DYNAMIC BRAKING RESISTORS

The purpose of Dynamic Braking Resistors (DBR) is to slow down, stop or decelerate electric motors in a short period of time. In comparison with mechanical braking systems, Dynamic Braking Resistors have a series of crucial advantages, such as:

- Higher reliability and less maintenance required

- Less weight

- Faster braking process

DBRs typically fulfill their purpose through rheostatic braking. This means that the resistors absorb part of the electric energy generated by the motor, releasing it in the form of heat and thereby obtaining the decelerating effect.

APPLICATIONS

Braking resistors are vital when mechanical and friction-based braking is not enough. For instance, they are crucial when the sheer masses in motion are such as to generate considerable amounts of inertial kinetic energy. Therefore, in contemporary industry they be found in:

- railway vehicles and electric cars

- tower cranes and mobile cranes

- wind turbines

- large textile manufacturing machinery

- lifts and elevators of various kinds.

FAIRFILD’S DYNAMIC BRAKING RESISTORS

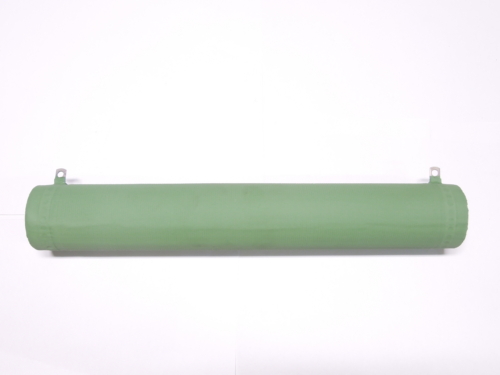

Most of Fairfild’s Braking Resistors are based on the wire-wound constructive model. Among the most popular series, there are:

- RFD, RFK and RFH series: Wirewound on mica plates, filled with quartzite sand and sealed with silicone plug

Power ratings: between 50 W to 700 W

Ohmic values: between 0.25 Ω and 51k Ω. - RFZ/C, RAF and RDF series: Wirewound as a spring, filled with fused alumina and sealed with dielectric cement.

Power ratings: between 75 W and 550 W

Ohmic values: between 1.1 Ω and 510 Ω.

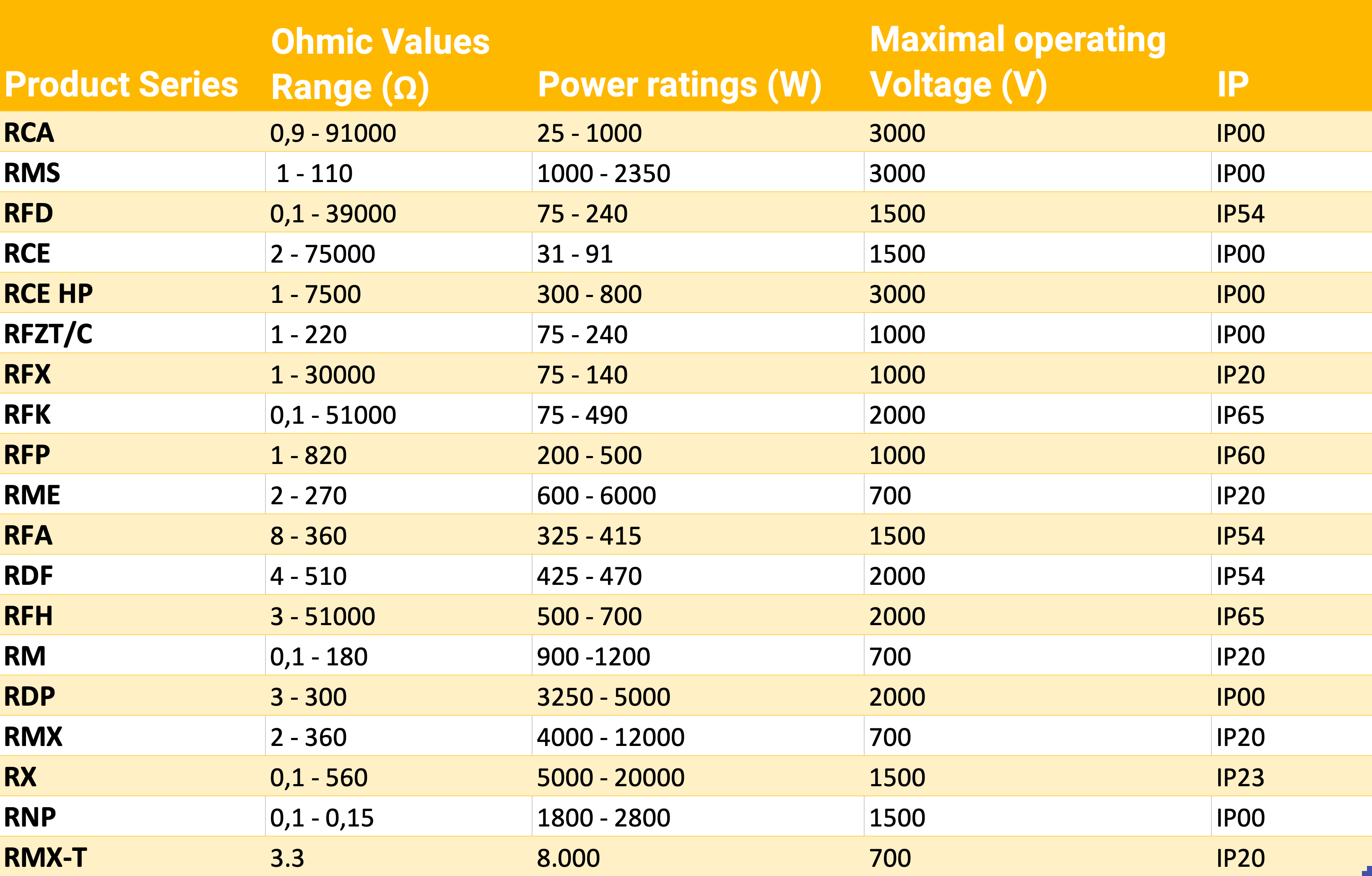

For an overview of all the product series suitable for braking, consult the chart below. For examining each model’s specifics, use the menu on the left.